New Sustainable Bioelectronics Revolutionizes Wearable Technology

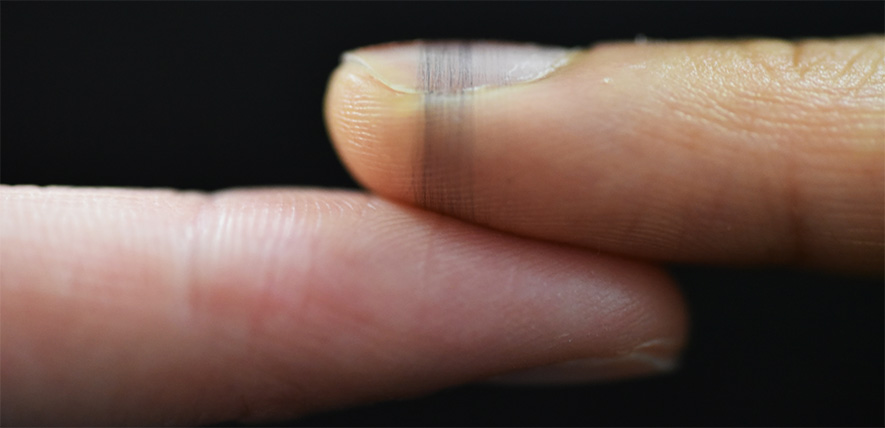

A groundbreaking new method for creating imperceptible sensors from ‘electronic spider silk’ has been developed by researchers at the University of Cambridge. Inspired by the conforming and sticky nature of spider silk, these bioelectronic fibres are at least 50 times smaller than a human hair. They are so lightweight that they can be printed directly onto surfaces without collapsing the structure, such as the fluffy seedhead of a dandelion.

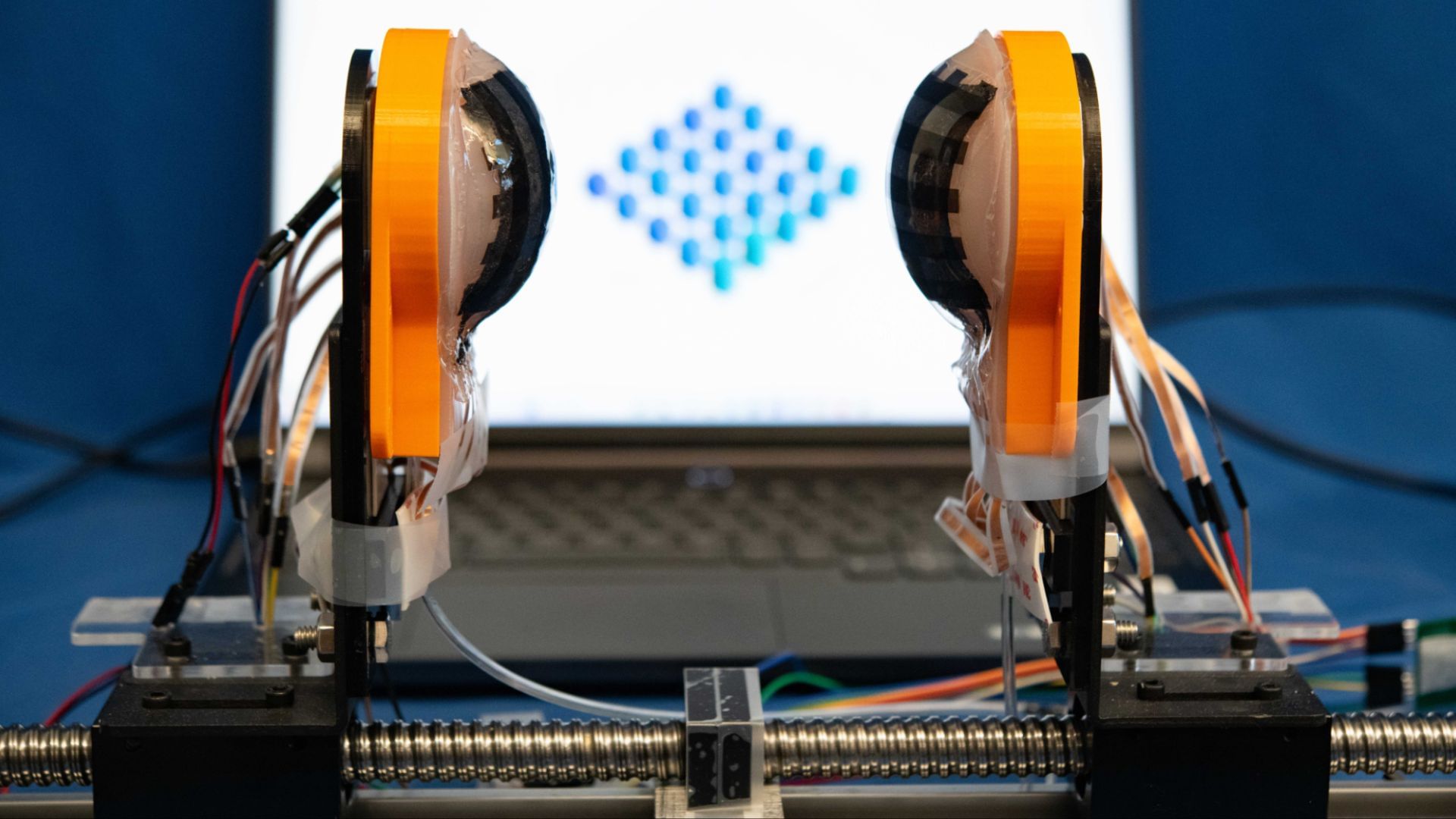

These innovative sensors can be printed onto human skin, conforming seamlessly and exposing sweat pores without the wearer even realizing they are there. This technology opens up a world of possibilities in various fields, from healthcare to virtual reality, electronic textiles, and environmental monitoring. The imperceptible nature of these sensors could revolutionize how we interact with the world around us, offering continuous health monitoring, improved sensory experiences in gaming and virtual reality, and much more.

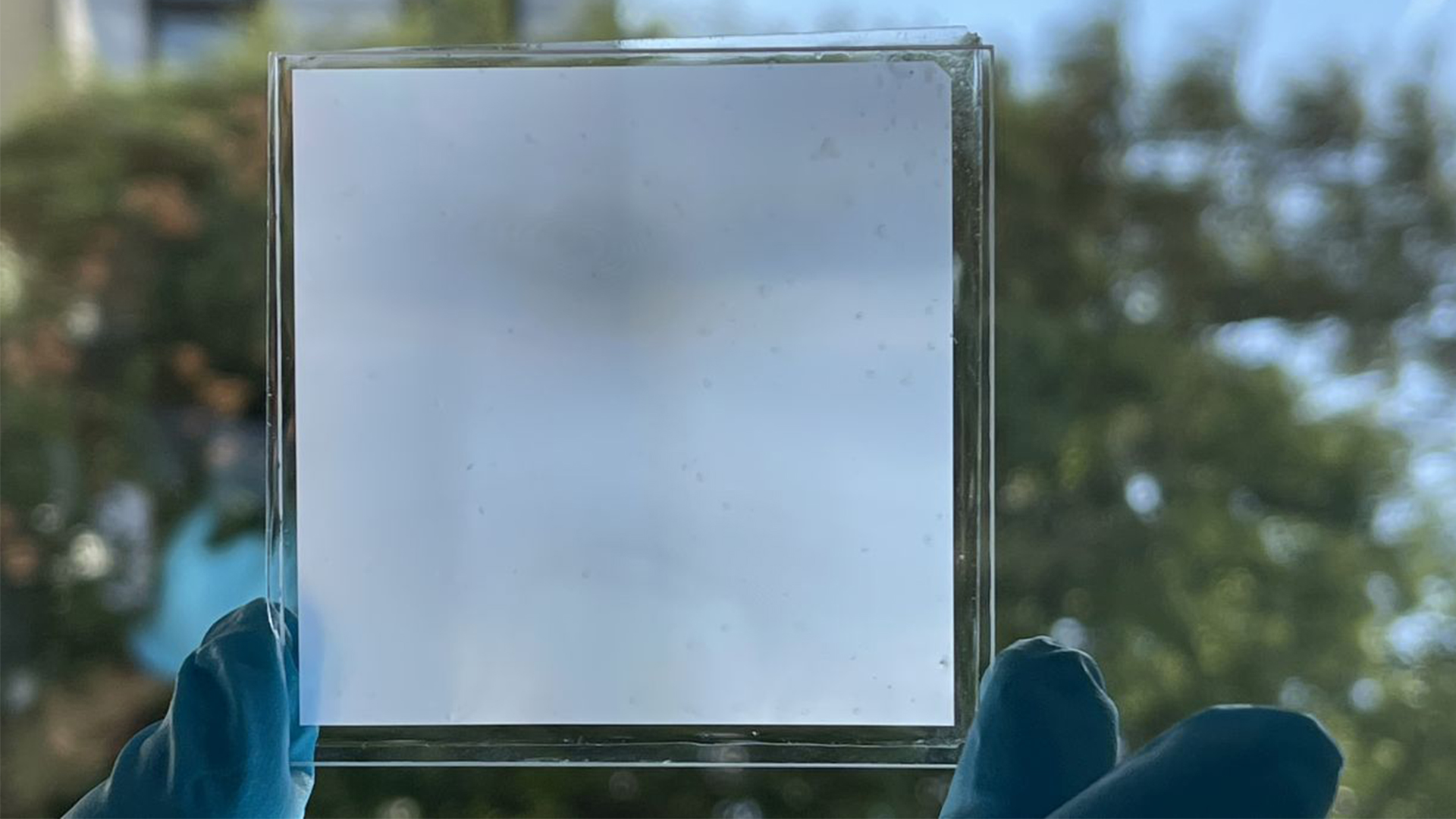

The bioelectronic fibres are produced using a sustainable, low-waste method that is far less energy-intensive than traditional sensor manufacturing processes. They can be customized to fit a wide range of biological surfaces, from fingertips to dandelion seedheads. These sensors are high-performance, repairable, and generate minimal waste, making them an environmentally friendly alternative to current wearable technologies.

The implications of this research are vast, with potential applications ranging from health monitoring and precision agriculture to environmental monitoring and beyond. The ability to integrate other functional materials into this fibre printing method opens up even more possibilities for the future of wearable technology.

Revolutionizing Wearable Technology with Imperceptible Sensors

Researchers at the University of Cambridge have developed a game-changing new method for creating imperceptible sensors from ‘electronic spider silk.’ These bioelectronic fibres, inspired by the conforming and sticky nature of spider silk, are lightweight and can be printed directly onto surfaces without interfering with the structure. This innovative technology opens up a world of possibilities in various fields, from healthcare to virtual reality, electronic textiles, and environmental monitoring.

The bioelectronic fibres are produced using a sustainable, low-waste method that is far less energy-intensive than traditional sensor manufacturing processes. They can be customized to fit a wide range of biological surfaces, from fingertips to dandelion seedheads. These sensors are high-performance, repairable, and generate minimal waste, making them an environmentally friendly alternative to current wearable technologies.

The ability to integrate other functional materials into this fibre printing method offers even more potential for the future of wearable technology. The imperceptible nature of these sensors could revolutionize how we interact with the world around us, offering continuous health monitoring, improved sensory experiences in gaming and virtual reality, and much more.

Cambridge Researchers Develop Imperceptible Sensors from ‘Electronic Spider Silk’

Researchers at the University of Cambridge have made a significant breakthrough in wearable technology by developing imperceptible sensors from ‘electronic spider silk.’ These bioelectronic fibres, inspired by the conforming and sticky nature of spider silk, can be printed directly onto surfaces without interfering with their structure. The lightweight and high-performance sensors have the potential to revolutionize various fields, from healthcare to virtual reality, electronic textiles, and environmental monitoring.

The sustainable, low-waste method used to produce these sensors makes them an environmentally friendly alternative to traditional sensor manufacturing processes. The bioelectronic fibres can be customized to fit a wide range of biological surfaces, from fingertips to dandelion seedheads, and are repairable and generate minimal waste. By integrating other functional materials into this fibre printing method, the researchers have opened up new possibilities for the future of wearable technology.